EXCAVATION WORKS

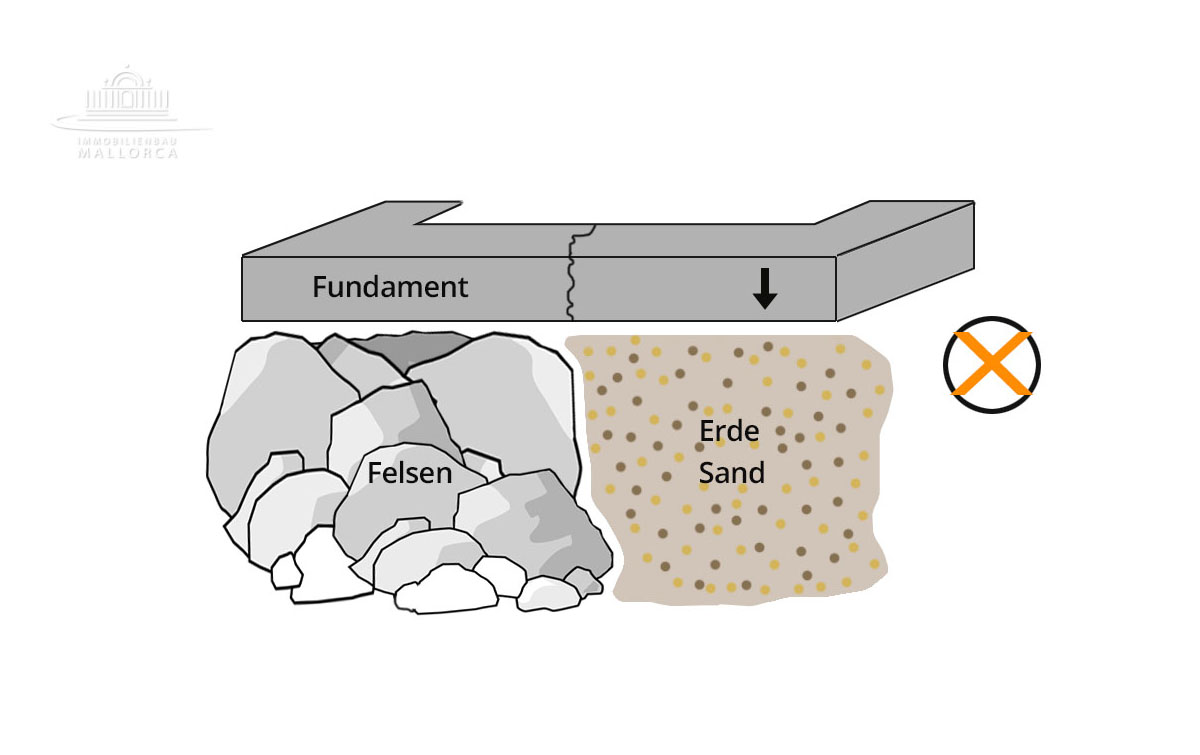

In general the implementation of the excavation is not commenced before soil samples have been taken and the architect's requierments are known. The depth of the excavation is determined by these factors.

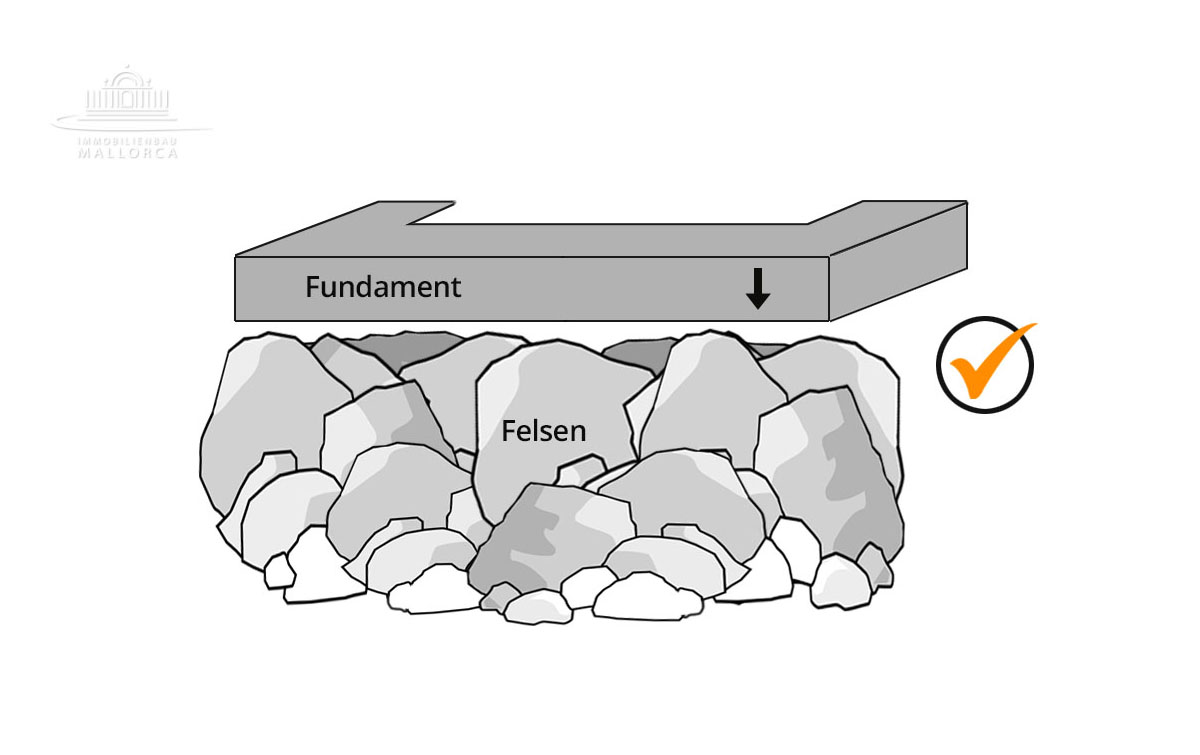

Mallorca consists mostly of rocky or stony ground - from soft sandstone up to very hard stone. In general, the closer to the coast - the harder the substrata -

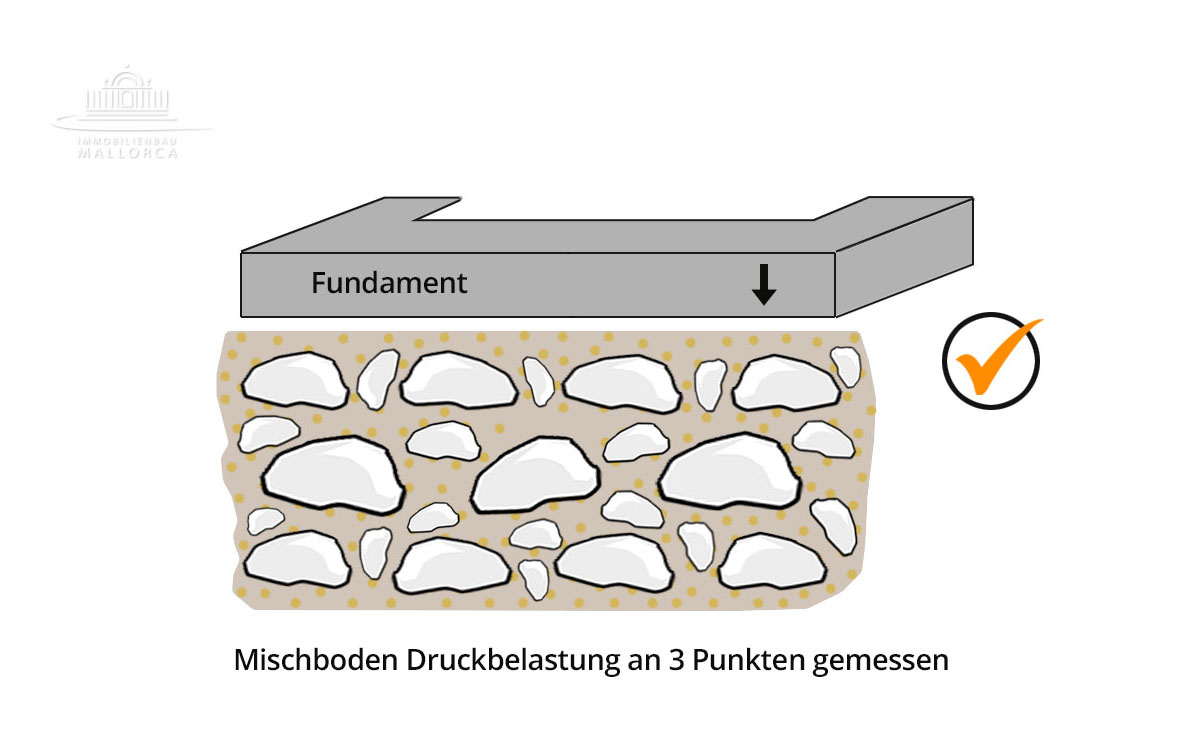

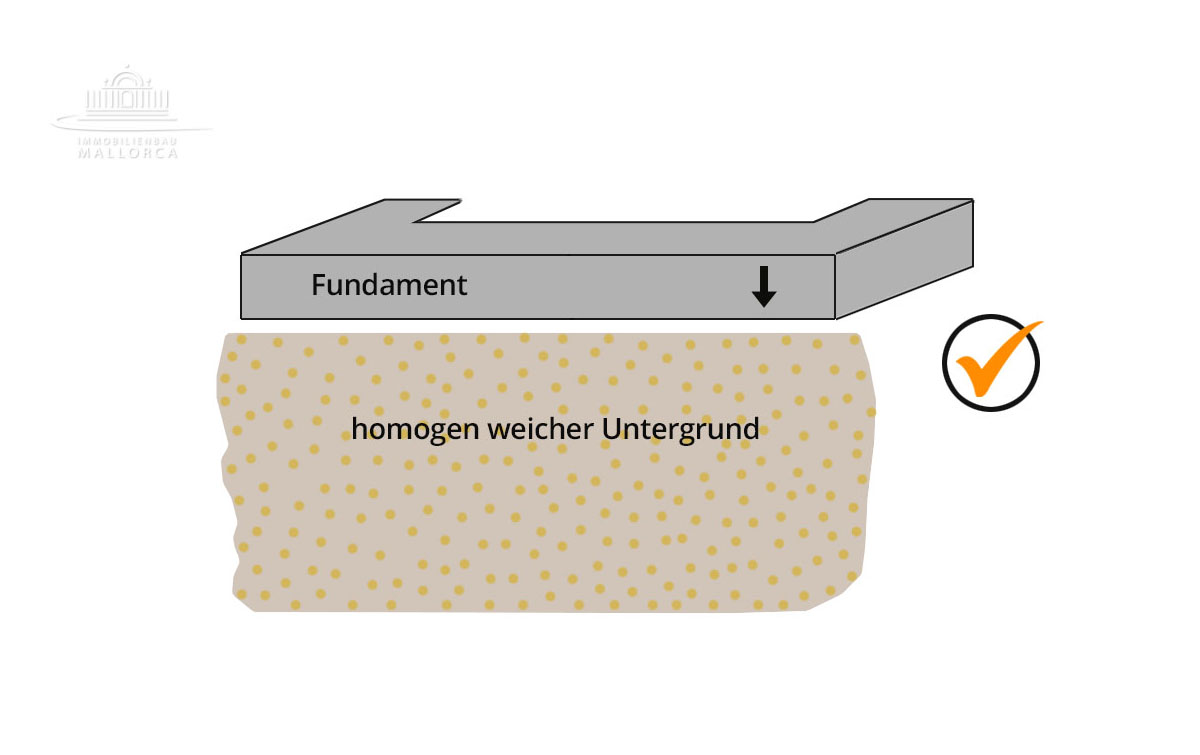

For the builder the homogeneity of the soil is the decisive factor. Once the soil sampels indicate a (resilience of kg/ cm3) it is possible to excavate to a depth, at which similar tensions are provided for the foundations. The more balanced the tensions, the more even your foundations.

FOUNDATIONS

To understand the geological composition of Mallorca better, here is an explanation of the substrata.

It is easy to see that after - a superficial depth you often find a hard layer of rock in Mallorca. Even with normal rain the water seeps away, and then, when it meets resistance, makes its way back to the earth's surface. For this reason the protection of humidity from the soil is important when constructing a house in Mallorca. We distinguish between the following foundation types in the single family house section:

Variety A) Filled strip foundations

Strip foundations carry the support, for the walls and the roof construction. The cavities, are filled and compacted, and first provided with a clean layer of cement. Than loaded with a barrier layer, which goes through the wall washers and afterwards poured out with an reinforced ground plate. We usually use this foundation type for garages, small buildings, pool houses, outside areas etc., and process certified barrier layer products, which means with release for the use at new constructions, which fulfill the current construction requirements.

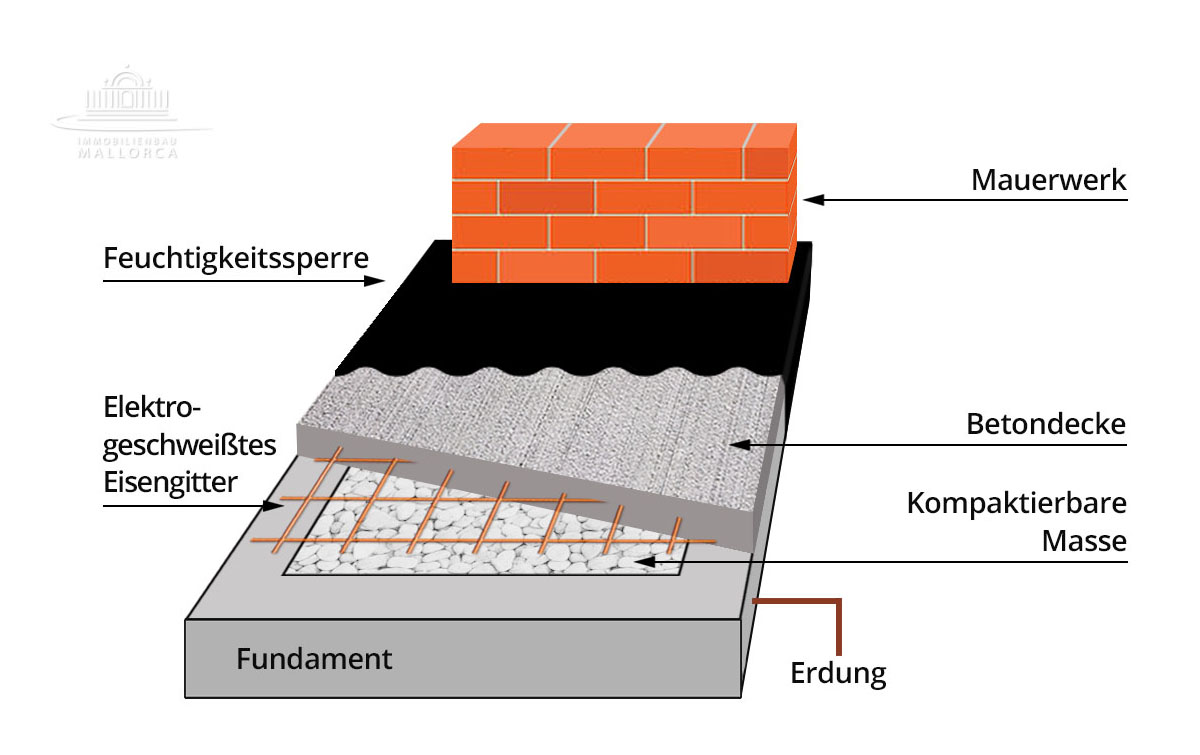

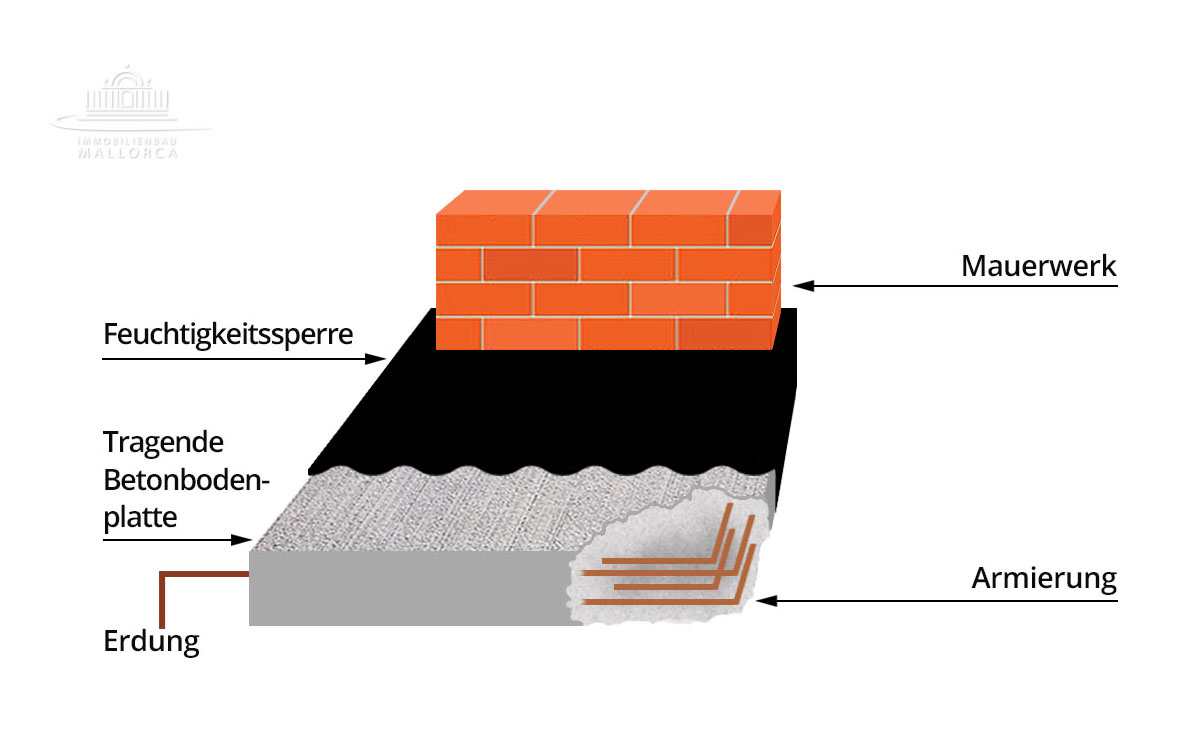

Variety B) Continuous concrete ground plates

Independently either with or without underlying strip foundations, your house can be built on a continuous reinforced concrete ground plate. This type of foundation provides a continuous “horizontal barrier” and is protected against running water and rising humidity. This is one of the highest quality methods of construction that can be found on the market and offers maximum protection.

Reinforced ground plate, as the name suggests, means an iron reinforced concrete layer. This uses quality class concrete and in addition iron netting for the structure of the building. Shortly explained the ground plates which are set up on the wall plates intercept for a corresponding iron construction.

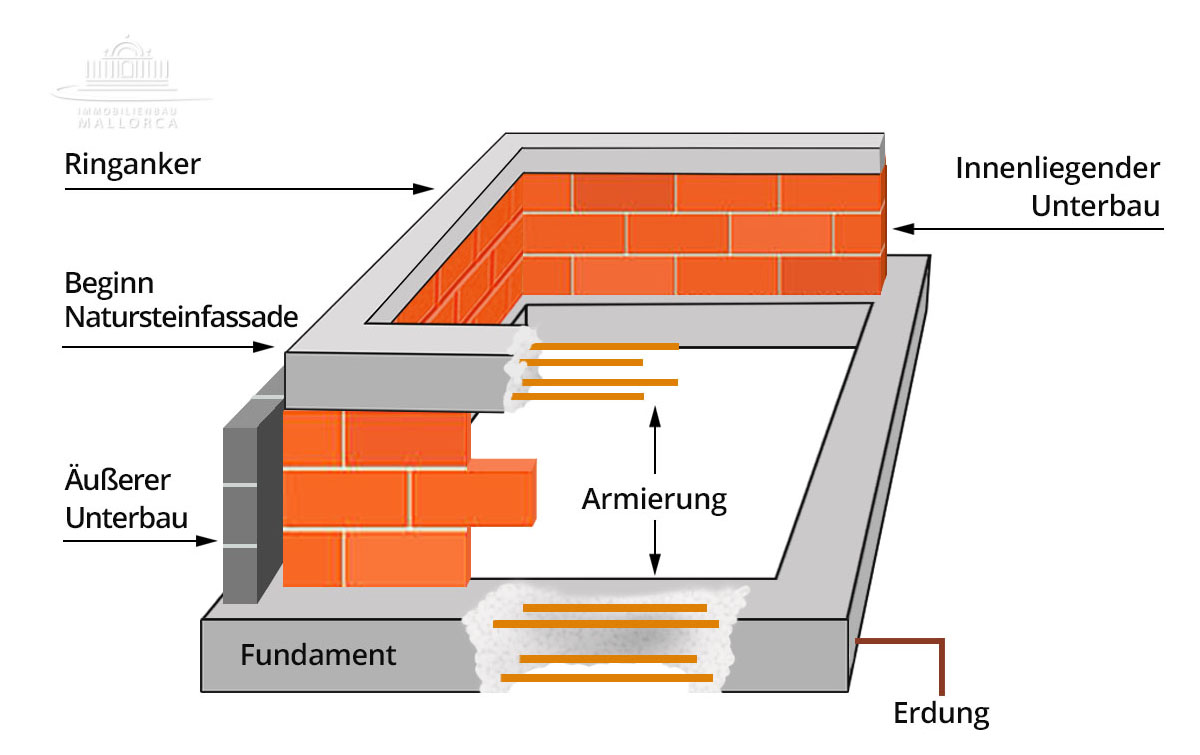

Variety C) Increased Foundation

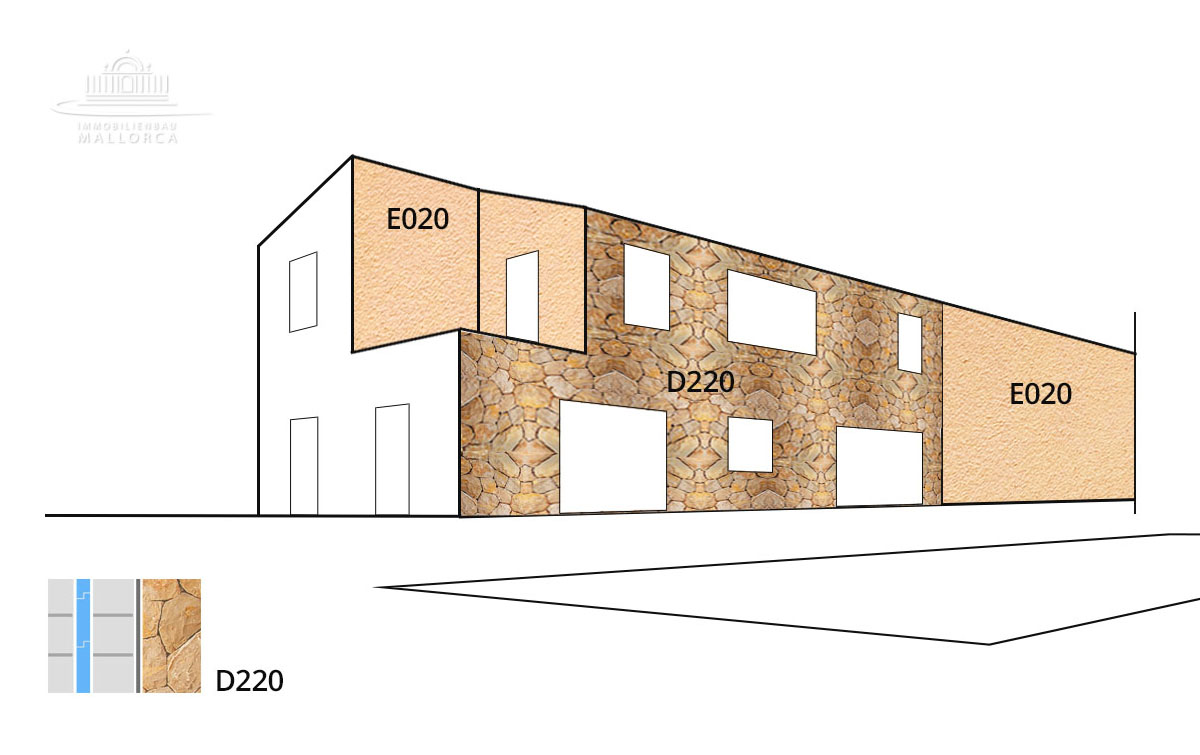

At our standard house types (E020, D110, D220, T320) the “increased foundation” is always used:

After the underlay concrete, the shuttering is installed in the excavated earth level. Iron, as project specification for kg/m3, earthing, concrete quality class as planned, from concrete plant and vibrated on site.

Massive full-carrier block stone masonry, also called “bloques áleman”.

A line for inboard block stone masonry and a line for the natural stone covering at house type D220, T320. The increased foundation is closed off with surrounding wall ties, in the price included is a total hight of approximately 80 cm including the wall ties plus foundation strips.

Important: Hanging cover installations are done, wherever possible and where sufficient ventilation of the increased foundation is guaranteed. We feel free to change the foundation type depending on the excavation.

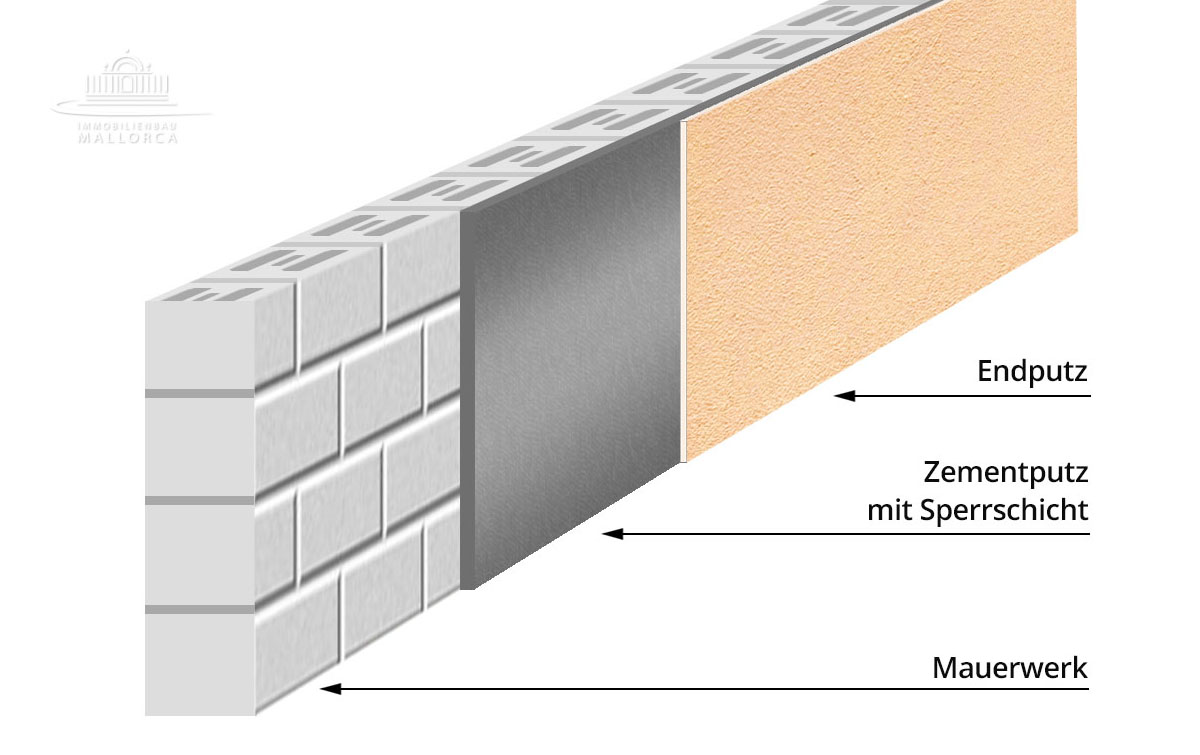

Type E010

Massive full-carrier block stone masonry (20cm strong), also called “bloques áleman”, plastered from the inside. From the outside cement plaster with humidity barrier (up to 1 cm), and fabric-reinforced external plaster.

If you wish, garages and outbuildings (like machine-rooms and so on) can be constructed with uninsulated single-shell block stone masonry or alternatively sandstone masonry.

It is recommended to make a building usage analysis, to ensure that the construction type is suitable.

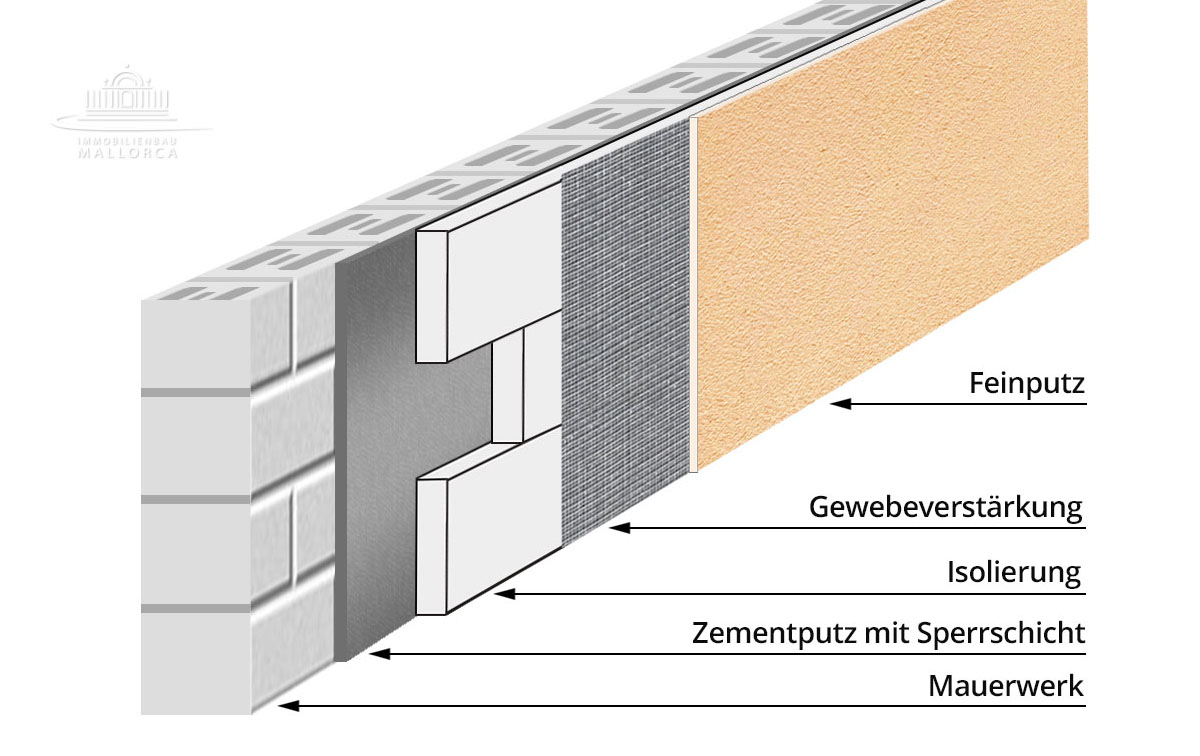

Type E020

Massive full-carrier block stone masonry (20cm strong), also called “bloques áleman”, plastered from the inside. From the outside cement plaster with humidity barrier (up to 1 cm), isolation (here 6cm strong) and fabric-reinforced fine plaster. In Spanish this is known as “fachada SATE”, similar to the German thermal insulation system. Alternative material is from “Caparol Almareno 700” with Dalmata Poliestereno Espandido (density 20 and calibrated) or from the company “Isaval” in the same quality class.

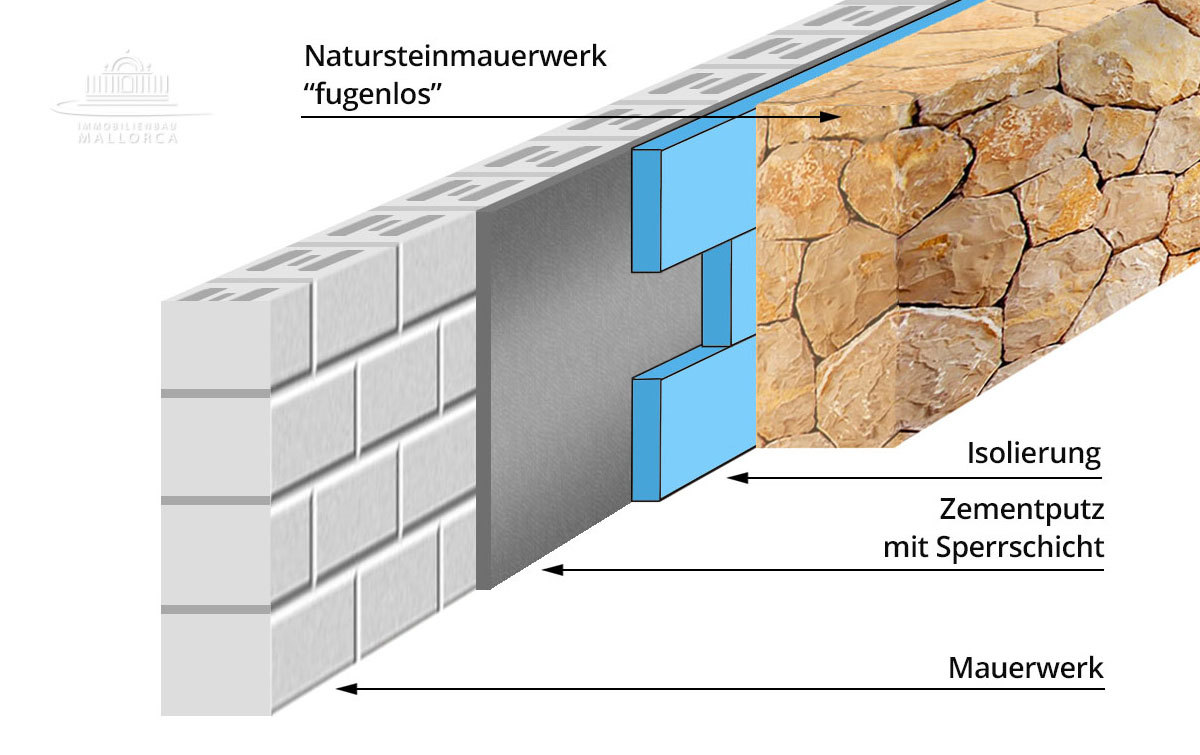

Type D220

Massive full-carrier block stone masonry (20cm strong), also called “bloques áleman”, plastered from the inside. From the outside cement plaster with humidity barrier (up to 1 cm), isolation (here 4,5cm strong), and before bricked approximately 25 cm nature stone masonry, self carrying, massive, fully stocked and filled with cement and colored mortar conclusion. The house edges, window and door borders decorated with mares stone as full material.

The natural stones can be formed to 90 degree angle to build the conclusion, or with mares stone cut to miter and decorated glued circulating. We process various ways and techniques.

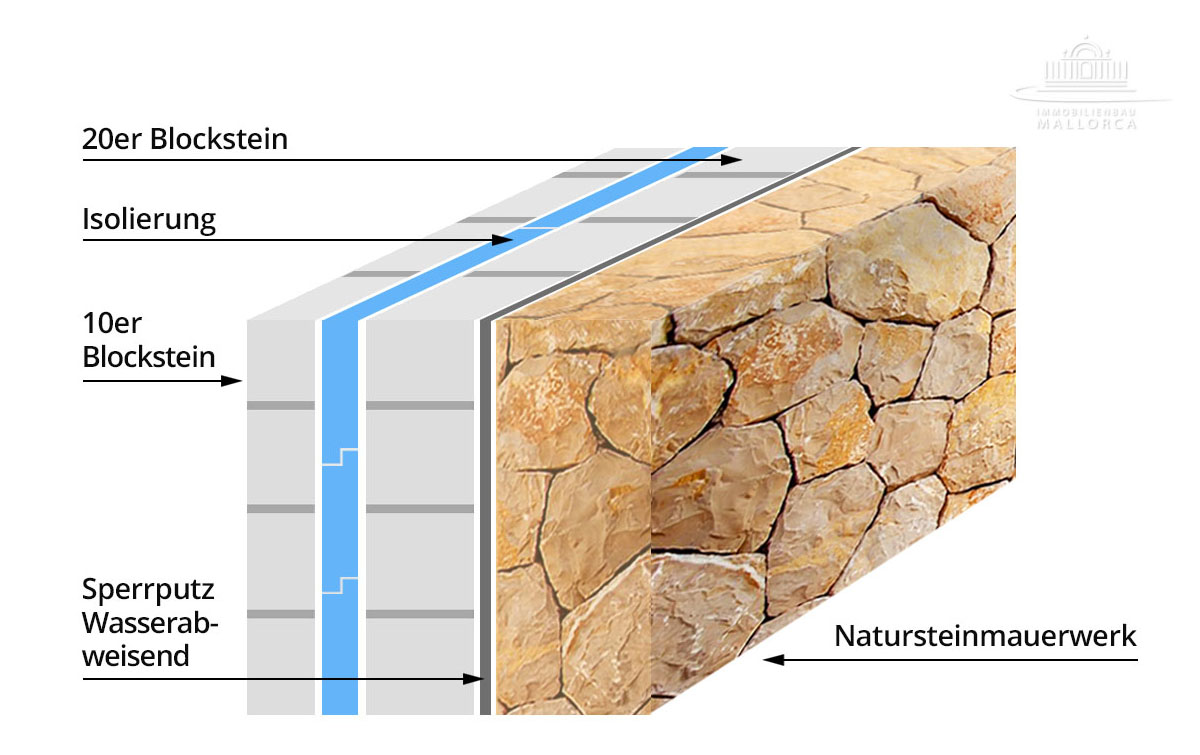

Type T320

Massive full-carrier block stone masonry (20cm strong), also called “bloques áleman”, isolated from the inside (here 4,5cm strong), and before bricked with an additional 10 cm nature stone masonry, plastered from the inside. From the outside cement plaster with humidity barrier (up to 1 cm), and before bricked approximately 25 cm natural stone masonry, self carrying, massive, fully stocked and filled with cement and colored mortar conclusion. The house edges, window and door borders decorated with sandstone.

The natural stones can be formed to 90 degree angle to finish or with sandstone cut to miter and decorated circulating. We use varying techniques as appropriate.

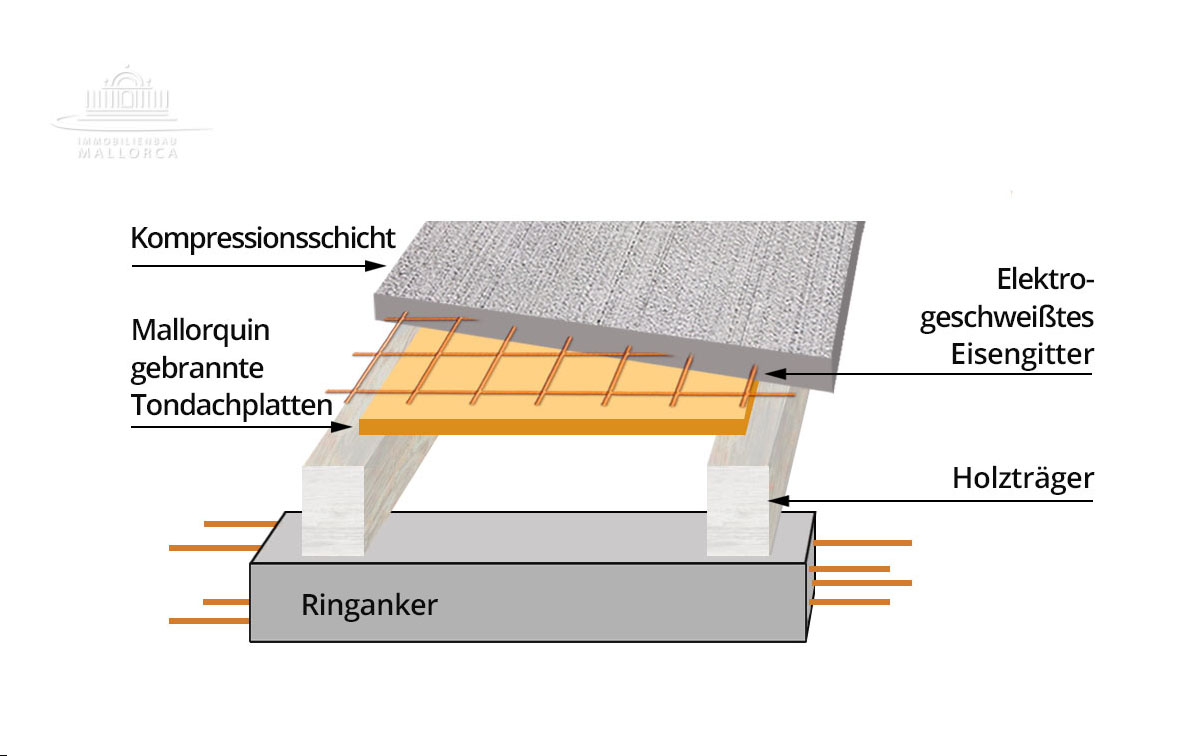

Version 1.2)

Wooden beams with clay records lying in between and covered with a combined concrete layer with strengthened electric welded iron mats. You can enjoy the view of the natural wood, seeing the strong beams interspersed with clay records, which are manufactured and fired here in Mallorca from local raw material.

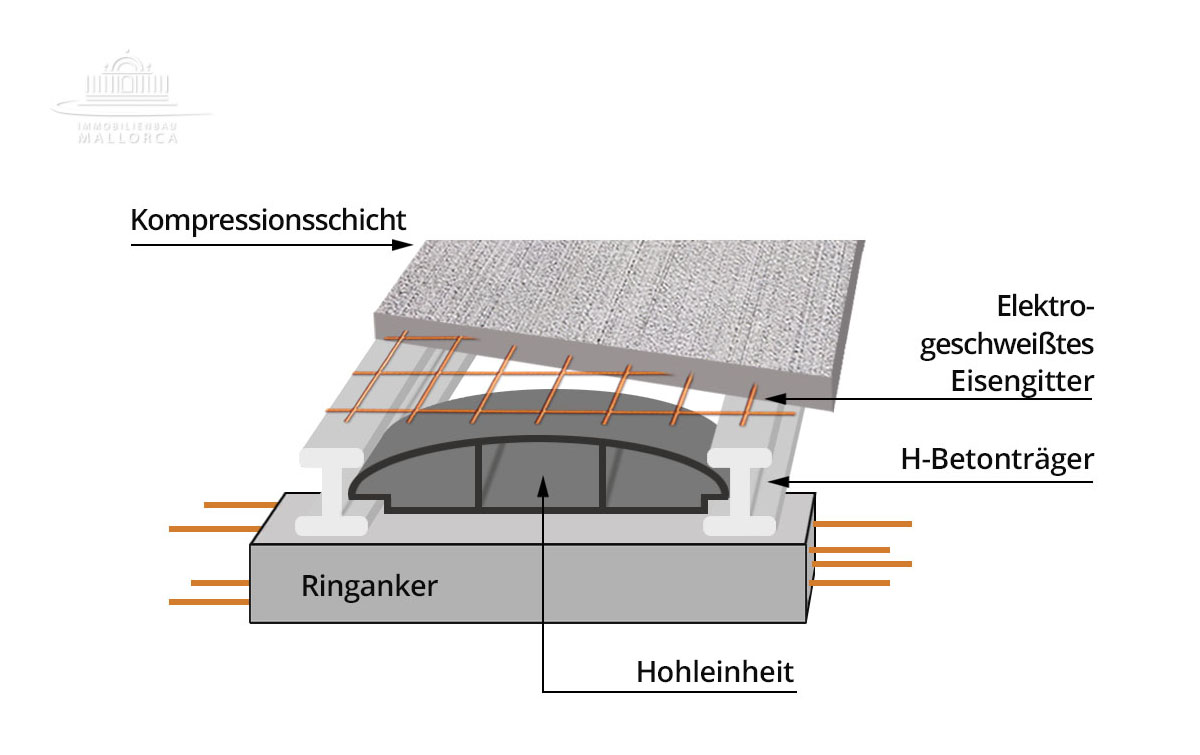

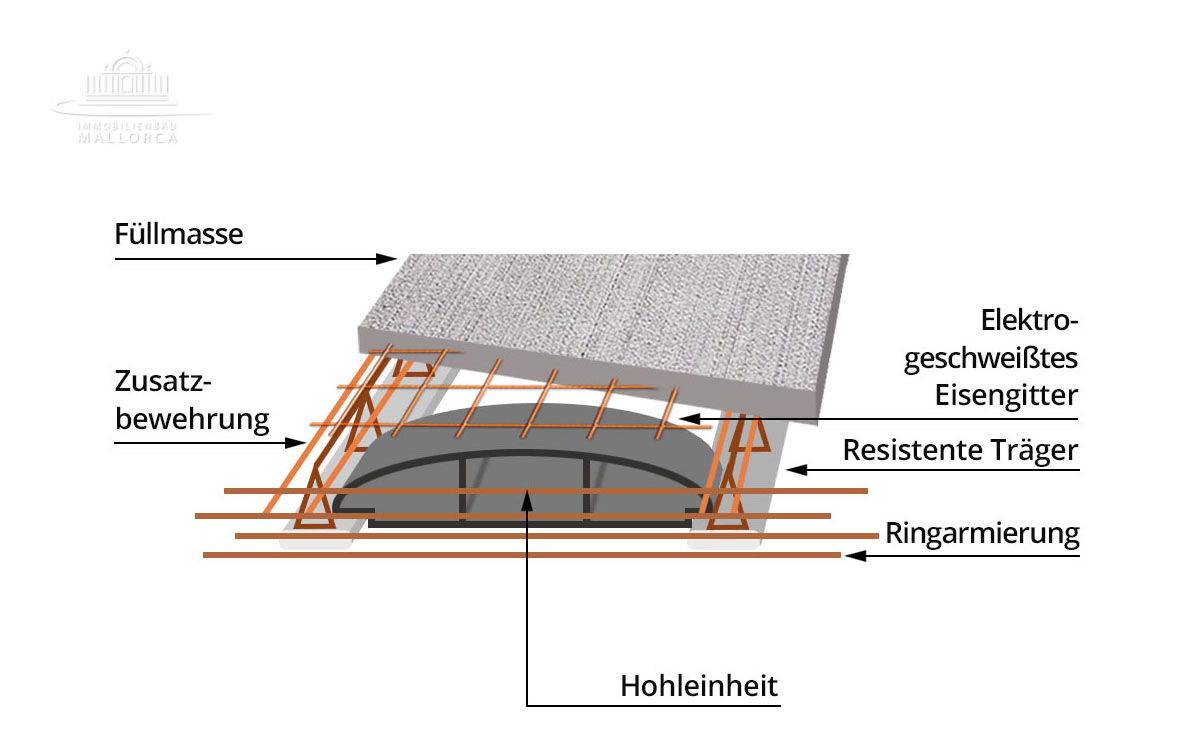

Version 2.1)

Prefabricated uni-directional concrete beams (resistant beams), with extended ends fitting into the ring anchor iron mesh, the interspaces filled up with hollow stone elements, interspaces with strengthened iron and on there lying complete and distributed electric welded iron mats. Here the static ceiling and the combined-concrete-layer are poured out to one unit. The visible underside is plastered. This roof-construction-system can be compared with the construction of a brick ceiling.

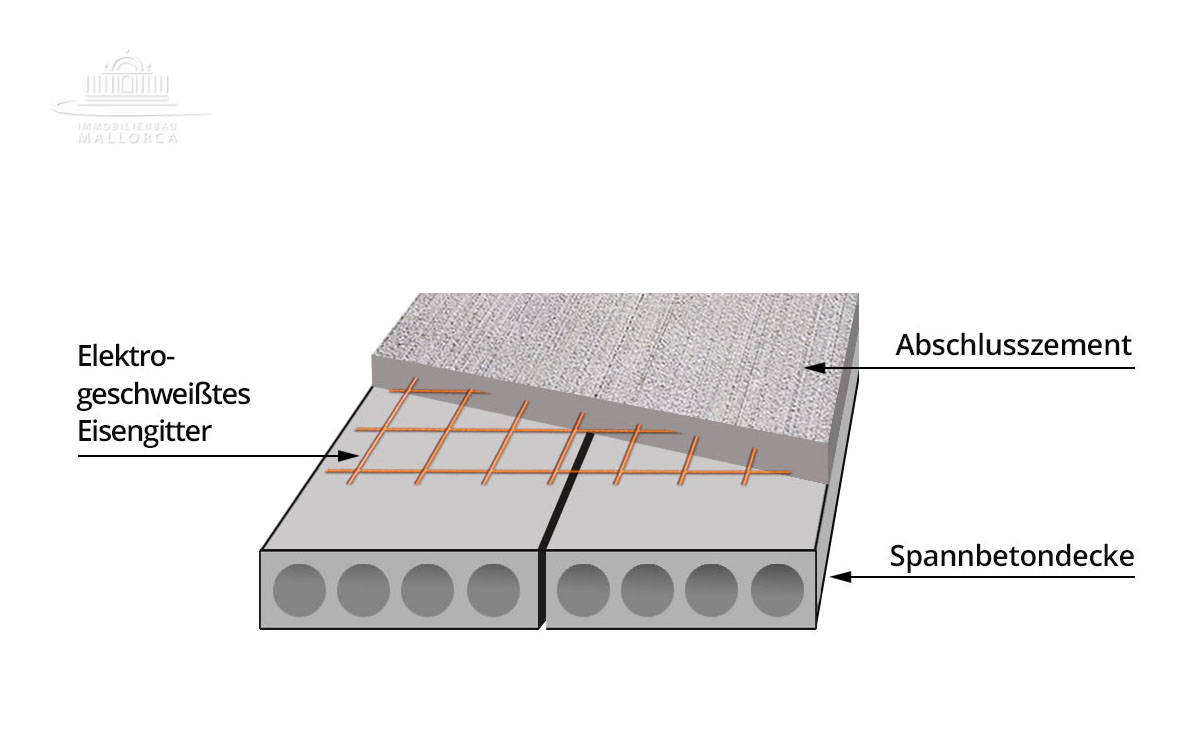

Version 2.2)

Tension concrete – final-ceiling with circulating ring anchors – recommended for roofes over 5,5/6,0 meters. The ceiling constructions above work statically seen also for larger spans, but this way you lose the feeling of comfort. To avoid transmitting vibrations in the basement ceiling you work at middle ceilings with a span but approximately with 6,0 meter tension concrete ceiling. These do not just guarantee perfect statical hold by similar ceiling strength, but also avoid upcoming noticeable vibrations when entering, and increase the feeling of the construction quality. Another advantage of tension concrete ceiling, is the reduced amount of time required for installation. Even though the final ceiling can be walked directly, it is recommended to instal the screed and the flooring after the separating layer.

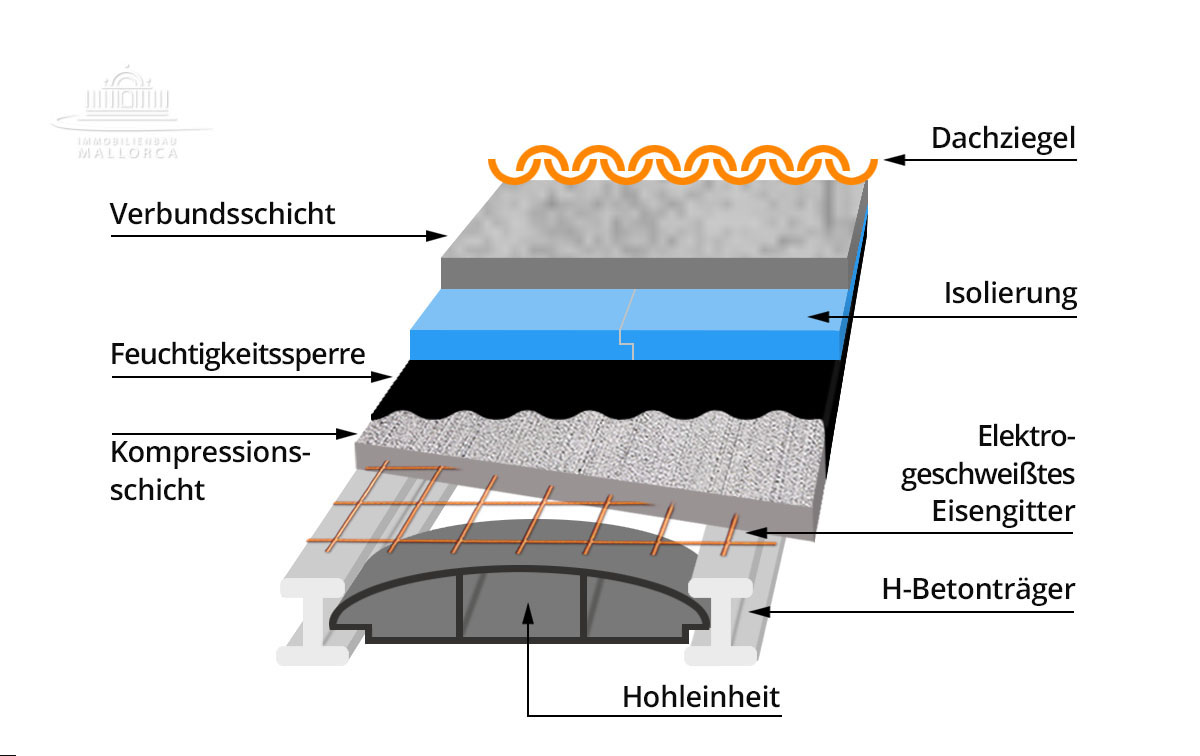

Version A

Prefabricated concrete-H steel beams with filled out interspaces through hollow block stone elements. Concrete layer with electric welded iron matts, PVC or asphalt foil to protect against water/ humidity. Insulation suitable to the particular type of house. Then a cement layer with fiberglass shavings is layerd on top amd finally roof tiles in the monk-nuns style.

We try to realize an easy changing construction system, which is similar to this, as in the description of version A!

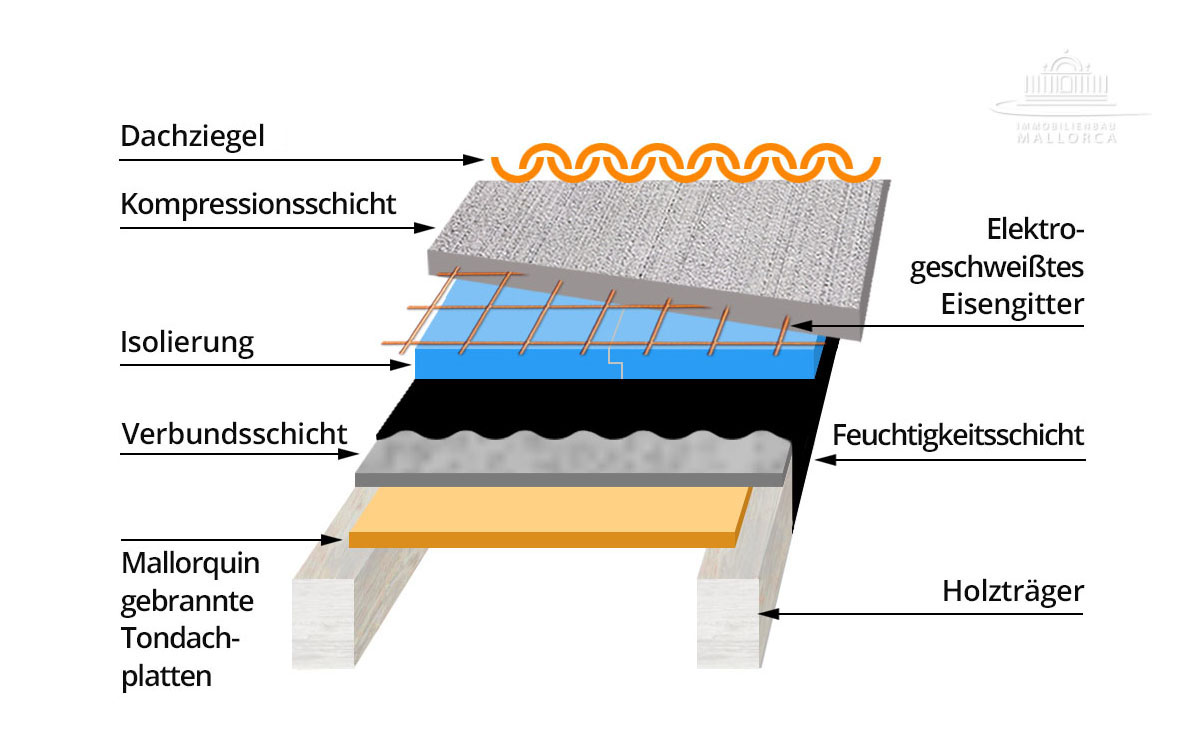

Version B

Wooden or concrete beam imitation wood, filled with clay tiles in between. Barrier foil and on top a concrete layer with chips. PVC or asphalt foil for sealing against the entering of water/ humidity.

Insulation suitable to the particular type of house followed by cement layer with fiberglass shavings and strengthened electric welded iron mats is added. Finally roof tiles laid with monk-nuns style.

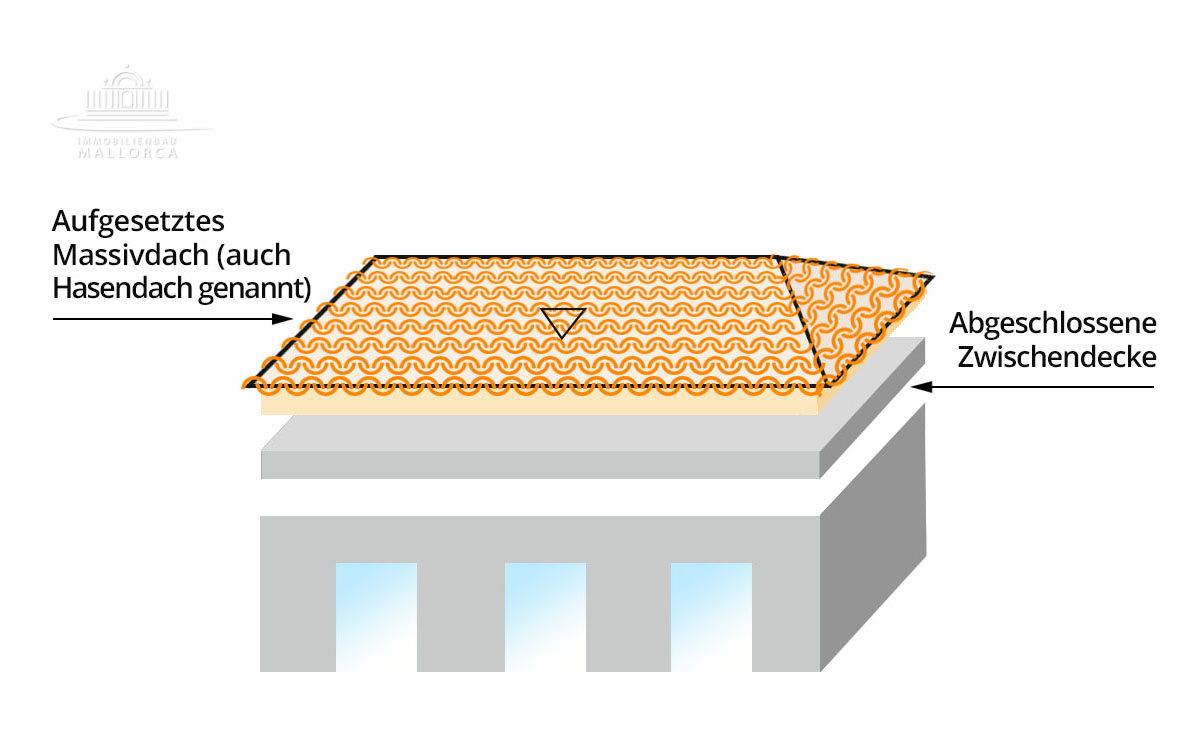

Version C

Middle ceiling installed as usual. Substantiated four-side or two-side slanted-roof construction (in Germany similar to the tent-roof or saddle-roof) with ventilation cavities. Easy burned clay plates laid with blocking foil. Concrete layer strengthened with shavings, PVC or asphalt foil to compact against water/ humidity and insulation suitable to the particular type of house followed by cement layer with fiberglass shavings and strengthened electric welded iron mats is added. Finally roof tiles laid with monk-nuns style.

Gutters and Downpipe

In Mallorca, gutters are usually not installed for aesthetic reasons – especially in porches / covered terraces (single-pitch roof).

In general, however, rainwater must be collected and drained. You can use materials like PVC-gutters or downpipes, in imitation copper / zinc etc.

For real estates in the higher class you should at least choose galvanized gutters or real copper gutters and downpipes. In our houses constructed with natural stone we use, if it is possible, clay burned gutters which have to be installed one by one and by hand.

We can explain to you the differences, advantages and disadvantages of each type.

Water and Humidity Barriers

We distinguish between welding foil, adhesive foil, textile with partly integrated steam barriers and paint.

Even though the techniques pursue the same goal, they strongly differ in the field of application and in the efficiency. When using the easy painting for the protection of an increased foundation, the two-component-painting is used for showers, roofs or pool renovation.

In order to combat the intrusion of humidity it should be done with the technical design. Foils, paint and special products – hence protection barriers – should be used to get higher efficiency. We can provide more information about this small but very important point in discussion with you.

It is important not to confuse humidity barriers with missing thermal bridges where condensation humidity and therefore mold can occur. These are different problems from the beginning, which have to be solved with different solutions!

Many materials / products are available on the market which can help protect against humidity. Below is a small overview of traditional and useful methods.

Injected (Nub) plastic, for the physical protection of humidity barriers, allows in addition for evaporation of the actual masonry.

Black bitumen painting, in combination with injected plastic, is ideal for the protection of the foundations but less appropriate for the sealing of bricked cellar rooms etc.

Two-component-painting is ideal for the substructure of showers and in wet areas. It is very appropriate for middle walls of outside facades and for flat roofs. Other two-component-paintings with epoxy mixture are ideal for pool renovation, without an additional layer. Renovation/ sealing of roofs as effective and fast process..

Asphalt foil, also available as welding-path, is ideal for the protection of the masonry against upcoming humidity, as an humidity barrier for terraces, balconies and roofs etc.

PVC-foil is used as an alternative application to asphalt foil, and is especially ideal for roofs or as a middle barrier in the masonry against rising humidity.

Eprom-foil is ideal to seal and protect large floor areas, having high efficiency and longevity.

Stairs (Construction)

In cold countries the stairs are boarded and iron-reinforced in their final form. Here in Mallorca it does not get that cold, so the roof sloping is made with steel reinforced concrete and the steps bricked onto it. For stairs in the inside and the outside. If you wish, we can design you a complete poured stair, which we recommend being cost effective and proven as a very good working technique.

Our outside stairs are finished with a slightly sloping gradient per tread, to avoid standingt water on the tread or in the corners.

We can construct concrete, wooden or steel stairs as you wish.

Disclaimer

The themes, concepts and hints described above are an explanation of different possibilities. Even though these are extensive, it is possible that your individual desires are not found here.

Your object is as individual as you are. The tailored solutions and specific construction methods are shown in detail in a contract specifically designed for you. Our contracts and objects are adapted to your requirements and are not comparable with any other.

Should you have any questions regarding your contract, do not hesitate, to contact us. We are in partnership with you throughout the whole construction period.